What Is Gasification?

Gasification is the science of converting solid, carbon-rich materials (such as agricultural residues, local biomass, or specific urban waste) into a valuable fuel called syngas or producer gas. This gas can provide reliable, on-demand energy for power generation, industrial heat, and sustainable chemical production. Our transparent, thoughtful engineering uses a controlled, heat-driven reaction inside the gasifier to deliver a continuous & efficient energy-recovery process.

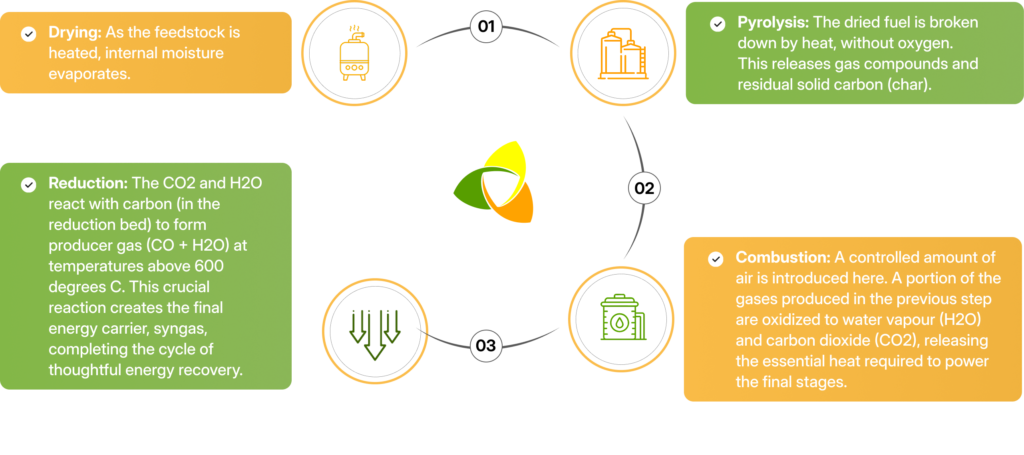

How it Works

4 Zones with Key Processes

Applications

Green Power

Our Gasifier converts diverse residues such as local biomass, municipal waste, and outputs from fecal sludge treatment into a clean, reliable producer gas/syngas through a controlled thermochemical process. The syngas is thoughtfully cleaned and cooled before reliably feeding a gas engine genset for decentralized power generation. In this process, we also create biochar (from biomass) or char (from MSW) as a useful by-product. Any excess gas is safely managed via a flare system, ensuring Hygienic Waste Management. This is our reliable solution for a low-carbon, circular future.

Green Process Heat

Our Gasifier is engineered to deliver reliable sustainable process heat by converting biomass or MSW into producer gas. This high-quality fuel can directly replace furnace oil, diesel, natural gas, and other fossil fuels in your kilns, dryers, and furnaces. The gas requires only minimal cleaning before it is sent to the burner system, with any excess safely flared. This process produces a valuable char by-product and provides efficient industrial heating with low emissions and a truly cost-effective solution.

Green Fuels & Chemicals

Our Gasifier can be utilized to convert syngas to fuels. Its clean output can be thoughtfully upgraded into high-value chemicals and energy carriers, including essential components for hydrogen production and methanol synthesis, alongside other sustainable fuels. This route solidifies the industry's necessary shift toward cleaner, greener chemical production, often called the core of Green Chemistry.

Carbon Sequestration

The Biochar we produce is key to a circular future. It aids to capture carbon reliably, locking it into a stable, lasting form. This allows us to support genuine carbon-negative technology. Beyond climate impact, this valuable material serves as an excellent soil amendment to enrich ecosystems, supporting sustainable agriculture and offering a clear path to generate certified carbon credits.

Municipal Solid Waste (MSW) Disposal

Our Municipal Solid Waste (MSW) and Refuse Derived Fuel (RDF) Gasification systems offer a truly purpose-driven approach to sustainable waste management and waste disposal/treatment. We convert MSW/ RDF into clean energy, significantly contributing to landfill reduction. This process empowers local communities and industries, driving us toward a fully functional circular economy.

Transforming Feedstock into Renewable Energy

The Gasifier thoughtfully converts biomass or MSW into clean producer gas. This output is engineered to directly replace conventional high-carbon fuels such as furnace oil, diesel, natural gas, or other fossil fuels. These serve as a reliable and sustainable source of heat across essential thermal applications, including kilns, dryers, and furnaces.

Get in touch

We’re Here to Help.